Pool-type research reactors are the key reactor types among the current multi-purpose research reactors in the world. They have attracted much attention due to their outstanding performance in safety characteristics, versatility, operation and maintenance. Among pool-type reactors, the design of small research reactors with a thermal power of 1~10 MW is the most mature and has the widest application scenarios. This study systematically analyzes the evolutionary trends of small-scale pool-type reactors (1~10 MW thermal power), focusing on core design innovation and application diversification. Firstly, various core schemes of small pool-type research reactors worldwide carried out under RERTR (Reduced Enrichment Research and Test Reactor) de-enrichment projects and core redesign projects are comparatively analyzed alongside the fuel types and component structures that can be used in the core of future small pool research reactors, so does the current applications of small pool-type research reactors around the world. Then, the development status of small pool-type research reactors in terms of fuel type and core structure together with the technical indicators of various neutron application scenarios of research reactors are summarized. Finally, through horizontal comparative exploration and analysis, it is concluded that the future small pool-type research reactor will adopt a compact core design, high-density low-enriched uranium as fuel, based on a compact and movable small core, and with neutron source application facilities in large pools as the main development direction.

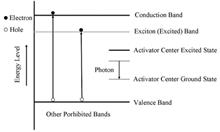

As an advanced radiation therapy technique, proton therapy is valued for its precise dose distribution and minimized damage to surrounding normal tissues. Accurate dosimetry of proton beams is crucial to ensure treatment efficacy and safety of proton therapy. Fiber optic dosimeters have become a hotspot for proton therapy dosimetry research due to their unique advantages, such as high spatial resolution, real-time monitoring capability, water-equivalence, and resistance to electromagnetic interference. In this paper, the technical principles, current application status, development challenges and future trends of fiber optic dosimeters in proton therapy dosimetry are reviewed to provide researchers and clinicians with a comprehensive perspective to improve the accuracy and therapeutic efficacy of proton therapy. Firstly, the luminescence mechanisms of fiber optic dosimeters are outlined and their working principles are briefly described. Then, based on different luminescence mechanisms in clinical proton therapy, the utility of fiber optic dosimeters is discussed for high dose rate adaptability and accuracy. Meanwhile, the challenges and solutions are addressed to the current fiber optic dosimeter technology, such as applying burst quenching correction reduce the burst effect. Finally, the future development of fiber optic dosimeter technology is prospected, especially for its potential application in ultra-high dose rate treatments such as Flash therapy, and how existing limitations can be overcome through innovations in materials science and optoelectronic technology.

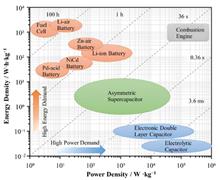

Supercapacitors (SCs) are highly efficient energy-storage devices that enable rapid energy storage and release through ion adsorption at the electrode-electrolyte interface or fast faradaic reactions. Despite their great application potential, the development of this novel electrochemical energy storage technology has been limited by insufficient understanding of the fundamental charge storage mechanisms. Synchrotron radiation has a number of excellent characteristics, such as high brightness and coherence, wide energy range, and large redundant space for equipment integration; thus, various material characterization techniques based on synchrotron radiation have been developed. These techniques can provide the morphological structures, particle sizes, crystal structures, electronic structures, and local coordination environments of specific material elements as well as powerful technological support for in situ/in-operando material studies. This review introduces the application of in situ synchrotron radiation characterization methods applied to SC research in recent years. These methods include in situ X-ray diffraction (XRD), in situ X-ray absorption spectroscopy (XAS) and in situ small-angle X-ray scattering (SAXS). This article also presents an outlook for future applications of in situ X-ray imaging and pair distribution function techniques and discusses the prospects and key roles of in situ synchrotron radiation techniques in designing high power/energy density electrode materials for advanced SC devices.

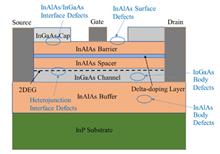

Indium phosphide (InP)-based high electron mobility transistors (HEMTs) have been widely adopted in space communication systems such as satellites, manned spaceflight, and deep space exploration due to their high frequency and gain, and low noise. However, high-energy particles such as protons, electrons, and neutrons in a space environment affect the performance of InP-based HEMTs and reduce the reliability of space communication systems. This paper mainly discusses the influence and degradation mechanism of defects induced by high-energy particle irradiation on the direct current (DC) and radio frequency (RF) performance of InP-based HEMTs, as well as the transconductance and kink effect in the irradiation environment. Subsequently, the research progress of radiation-hardening measures for InP-based HEMT devices is summarized and analyzed so as to provide the theoretical guidance for studying damage mechanism of InP based HEMT irradiation effect and improving its radiation-hardening technology. Finally, based on current challenges in the field, future research directions are proposed for radiation effects and radiation-hardening technologies of InP-based HEMTs.

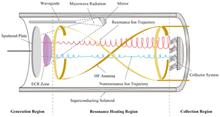

Since the ion cyclotron resonance isotope separation (ICR-IS) method was proposed in 1970s, it has received widespread attention from researchers and industries around the world. Based on the published results on the ICR-IS in the past few decades, a review is presented in this paper including the fundamental theories of ICR-IS, basic structures of the devices, major criteria for obtaining significant isotope separation effects; and in particular, the recent progress in the theoretical and experimental research fields for obtaining different isotopes using the ICR-IS approach is summarized and discussed. And finally, the key scientific and technological issues in future research for promoting industrial applications of the ICR-IS method are discussed briefly.

In multiple important fields such as industry and homeland security, traditional single ray imaging technology often only provides limited image information and material analysis, making it difficult to meet the growing demand for non destructive detection. With the continuous advancement of technology, various ray fusion imaging techniques have emerged, which can comprehensively obtain richer detection information, thus gradually attracting widespread attention from scientists around the world. This article first provides a detailed introduction to the basic principles of X-ray and neutron fusion imaging technology, and elucidates its advantages in material identification and structural analysis. Secondly, by reviewing the development history and application status of X-ray and neutron fusion imaging technology in China and other countries, the research progress and application examples of different countries in this field are comparatively analyzed. Subsequently, the main achievements of the current research are summarized, and some issues in the existing research plan are pointed out, such as the complexity of data processing and limitations in imaging accuracy. Finally, the future development of X-ray and neutron fusion imaging technology is discussed, and possible technological innovation directions and application prospects are discussed.

The corrosion of reactor alloy materials is directly related to the safety and lifetime of the reactor and has been extensively researched. However, experiments alone are insufficient to clarify the corrosion mechanism and predicting the corrosion behavior with high accuracy is also difficult. With the development of computational materials science, simulation has become a new tool in reactor alloy material corrosion research. Molecular dynamics methods can handle tens to hundreds of thousands of atomic scales, hence are suitable for simulating various surface and interfacial behaviors of many materials. Numerous applications in the field of reactor alloy material corrosion mechanism research have been conducted using molecular dynamics (MD) simulation in recent years. This review first introduces MD simulation methods, including classical MD methods, semi-empirical MD methods, and machine learning based MD simulations. Then, the research progress the MD simulation on corrosion of reactor alloy materials is described from aspects of MD methods applicable to corrosion simulation calculations, particularly reaction force fields, tight-binding quantum-chemical force fields, and machine-learning force fields; and the current status of corrosion research using MD methods to study the materials used in water-cooled reactors, liquid-metal-cooled reactors, and other environments, such as grain boundary element segregation, solid–liquid interface adsorption, and stress corrosion cracking. Finally, a summary and outlook are made on the prospective of MD simulation applied to the corrosion of reactor alloy materials.

After decades of research, the problems and behavior of the corrosion of reactor alloy materials under service conditions are clearly understood. However, some problems in corrosion of reactor materials have not been clarified, including the critical corrosion process of the reactor materials under operational conditions, the role of a single factor in the corrosion process, and the prediction of corrosion behaviors of new materials in extreme environments. The density functional theory (DFT), which is based on quantum mechanics, can be employed to accurately predict the motion process of atoms and the change in the relevant energy within a very short period. The DFT has become an important auxiliary method for investigating the corrosion process of reactor alloy materials in recent years and can help solve the above problems. In this paper, the DFT is firstly introduced, which mainly includes the theoretical basis, development process, and mainstream computational software. Then, a comprehensive discussion and analysis are conducted on the current research status of DFT applied to the corrosion of reactor alloy materials, including the adsorption, separation, combination, and internal diffusion of the reactor alloy material surfaces in the environments of water-cooled reactor, liquid-metal-cooled reactor, and molten salt reactor. Finally, future development trends of DFT application in the corrosion of reactor alloy materials are prospected.